Demo. Demo Forever: Daniel Kanter’s post on renovating his house is spot-on for anyone stuck in the middle of renovating. Example “One of the side effects of renovating an old house, I’ve found, is the way my brain has come to toggle between the absurd optimism I feel before a project begins and the extreme despair I experience when my ideas about how things will be collide with the reality of how things actually are.” From Manhattan Nest.

The Norwegian government retained Designit to help it streamline its immigration process in conjunction with the creation of a new agency, the Utlendingsdirektoratet or Norwegian Directorate of Immigration. The idea was to cut processing times by better managing data across multiple agencies, lightening the burden on the government while improving the "user experience" for would-be immigrants. Image courtesy of Designit.

Behrokh Khoshnevis, an engineering professor at USC, reveals his Contour Crafting fabrication process system, by which buildings, including plumbing and electrical utilities, can be built using what is in essence a large-scale 3D printer. Khoshnevis presented a scenario in which a 2,000-square-foot house could be completely framed in 20 hours, with lower construction costs than in conventional building methods.

"I pick the different elements for every build based on a few factors," says Evey. "One primary factor is color. Industrial parts are made in great colors like safety orange, dull gray, and high-visibility green, to name a few. The coloring of home product is typically very quiet, so I wanted to build lamps that went against that convention and made a statement."

"The design process starts by considering the amount of illumination needed, as well as the amount of physical space available. From there it’s a process of gathering components and materials," says Evey. "Next I experiment with composition and finishes until I have something both functional and formally intriguing. Then it is lovingly packaged and shipped off. Every Lighht is unique, so the process really changes from piece to piece."

"I started this project out of a desire to redefine the conventional aesthetics surrounding home objects. I wanted to challenge notions of both elegance and usability, and Lighht became a place for me to experiment with those ideas," Evey says. "Of course none of this takes place in a vacuum, I think of this work as sitting in dialog with more historical figures like Andrea Branzi, as well as contemporary designers like Martino Gamper and Brendan Timmins."

"From a formal perspective, I was seeing a lot of digital collage work created in a 'Home Depot aesthetic,' and I was curious what would happen when those visual gestures were re-crystallized and the digital made real once again," says Evey. "I’m interested in the cycles of creative culture relating to the Internet, and I think we’ve only begun to see the depth of influence digitally birthed aesthetics will have on the 'real' world."

Pia Wüstenberg, a German-Finnish designer based in London, created the Stacked Vessels we featured in the magazine, each made from ceramic, glass, and wood. Another project of hers we love is Processed Paper—a series of pendant lamps, table bases, and other pieces crafted from rolled wastepaper that she turns on a woodworker's lathe to create distinctive, marbleized pieces.

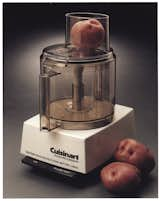

A pioneer in universal design, Pratt industrial design alumnus Marc Harrison "relied on hand-motion studies to redesign the Cuisinart food processor to meet the needs of consumers with disabilities." Other Pratt graduates, like Paul Mulhauser who worked on the OXO Good Grips line, have also ventured into the growing field of universal design.

For example, a designer specifies a certain stitch pattern. A sewer then creates the same pattern by hand giving feedback on reproducability. If it's too complex, he or she will offer feedback to the designer; the designer then takes another stab at the stitch's look. The back and forth happens until the detail is refined and meets the aesthetic standards and manufacturing capabilities at GM.

Hypetex Halo Chair

Utilizing a new carbon fiber process developed over several years by Formula 1 engineers, the Hypetex Halo chair by Michael Sodeau cuts an aerodynamic profile. Premiering at designjunction at the London Design Festival this year, these lounge chairs hint at the potential of such a flexible material.

1,472 more photos