Credits

From samira Sabulis

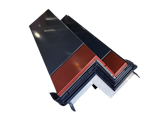

Dextall's recently completed project on 116th St. in Queens represents a major leap forward both for our company and for the prefabrication field at large. Working with client JLS Group , we were able to deliver a complete 55,000-square-foot facade for a 9-story, 55-unit apartment building in substantially less time, using substantially less labor and resources than a comparable development constructed with conventional means. Fabricated by our expert production team, Dextall's all-in-one exterior panels arrived onsite in New York just as the building frame was finished; once there, the next challenge was the unusually shaped lot, coming to a sharp point on its southern edge that would require the panels to meet at exactly the right angles. Dextall's DWall product not only threaded that technical needle, but brought an attractive, neighborhood-appropriate façade to the quiet Queens block, the panels' alternating swatches of aluminum cladding complementing the historic fabric of the streetscape. From design to fabrication to assembly, Dextall provided the client not only with a streamlined, easy-to-navigate construction process, but with a durable, high-performance exterior that will continue to pay dividends in energy and maintenance savings for years to come.

The success of the project can be summed up in a few figures. Jobsite labor involved only six crew members for the Dextall exterior assembly -- that's as compared to fully 47 trained workers that would have been required for a conventional exterior of a comparably sized project. The construction timeline was reduced by 15%, from twenty months to seventeen -- meaning apartments were ready for rent three months faster, and the client had three fewer months of paying carrying costs for loans and other payments. And since Dextall's exterior panels arrive pre-packaged and ready to install, the volume of material waste was reduced from the average 30% for most construction projects to effectively zero for the building exterior -- no messy, hazard-prone building site for neighbors and workers, and no needless carbon consumption for the environment. Net-net, the Dextall bottom line saved the building developer close to a $1 million, a result that's prompted the client to turn to us for their next project in Queens.