On a Rock in a Hard Place

On a cold, drizzly, late November morning in downtown Seattle, prefab buildings are not the first thing on most people’s minds—a roaring fire in a cozy cabin is more like it. But for Peter and Mark Anderson, of Anderson Anderson Architecture, the two aren’t mutually exclusive. Prefab, with its ambitious ideal as an everyman’s architecture, holds the promise of making that cozy cabin dream both accessible and affordable.

But the Seattle- and San Francisco–based architects have found that this dream is not necessarily the reality. "Low cost is what everyone thinks when they think prefab," Peter Anderson says with some chagrin. "We’ve been working with these building concepts for years, and while there is definitely a cost differential as opposed to stick-built structures, the homes we do are not what you would call cheap. Every house is different—different site, different client desires, different design—and with difference comes cost."

Despite Anderson’s frustration with the common per-ception of prefab as the "low-cost alternative," it’s also the reason so many are drawn to prefab. It’s certainly what brought Scott Stafne to the Andersons’ door. After seeing their Kennedy house on the cover of Dwell back in 2001, Stafne, a gruff, semi-retired lawyer who cut his teeth battling bureaucrats and insurance companies in Seattle, knew these were his architects. But the house Stafne desired was no ordinary structure, and the story of its development points to many of the obstacles standing in the way of modernizing the prefab housing industry.

In the mid-’90s, Stafne had acquired 360 acres of mountaintop land consisting of 16 buildable lots of 21 acres or more near Granite Falls, Washington, about an hour outside of Seattle, giving up his house in the city for the windswept, almost uninhabitable tract of land. But Stafne and his younger brother Todd, a former owner of a construction company in South America and earth-moving-equipment enthusiast, were ready to build. "There was nothing up there," Stafne explains. "Nothing except acres and acres of trees, wild animals, lakes, rivers, and waterfalls." While in some respects the site had everything, it had none of the most basic creature comforts—no electricity, no water, and no roads, save for a primitive logging road that wound up the exceedingly steep mountainside.

Cost aside, prefabricated construction seemed like the perfect solution to Stafne’s needs, given the difficult nature of the site and Stafne’s desire to keep it as pristine as possible. But, as Anderson explains, "That is another misconception people have about prefab—that it is a simple, quick, clean process. While there are definite advantages, the way the process has to be conducted now, it is still quite complicated."

The design of the Cantilever House, as it’s known, is based on a 14-by-86-by-22-foot steel frame resting on a 14-by-31-foot concrete foundation bolted to an existing rock. "That rock is really what allowed this to be such a unique house," says Anderson. "It’s what allowed us to cantilever the whole structure and take advantage of the site, pointing the house directly at the waterfalls, which are incredible."

An early estimate from one national steel company prior to engineering and further design of the steel frame, however, presented the first obstacle. An Arlington, Washington–based steel manufacturer, chosen for their proximity to the site, quoted the Andersons the manageable sum of $45,000—a number that seemed unrealistically low to the architects but stuck with Stafne. But when construction was set to begin—three years after this initial quote and the very early research that had confirmed the viability of the design concept—the turbulent steel market had caused the cost of the frame to spike considerably.

Frustrated but left with little choice, Anderson Anderson took the project to Seattle-based United Iron Works. The frame was now set to run upwards of $66,000, a significant jump from the original estimate and a big chunk of the $200,000 Stafne had hoped to spend on the entire project. But client and architect remained committed to the design scheme and the project continued.

With the framing issue solved, the architects turned their attention to panels. "We wanted to use SIPs [structural insulated panels] for everything," Anderson explains. The most noticeable part of the plan had the 4-by-22-foot panels hanging off the steel frame, acting as walls, their weight shared equally by suspension from cantilevered roof structure beams (which in turn rest on the steel frame), and by support from cantilevered floor structure beams (which cantilever out from the steel frame). The panels follow a simple pattern that leaves open space for dramatic floor-to-ceiling windows throughout the house. Once some of the Andersons’ more unique ideas for the SIPs were fully developed, their use for the floors, ceilings, and walls proved to be a huge time saver.

But before any of that could happen, the team had another problem to resolve. The steel frame made its way from Seattle to Granite Falls on the back of a tractor trailer, but once the truckers reached the area, they refused to scale the mountain: The unpaved road that ascended the grade by way of narrow switchbacks was more than they’d bargained for. The driver unloaded the frame and left it sitting at the foot of the mountain in the morning fog.

"We were a little stunned," says Todd Stafne. "That put us in a tough position and cost us thousands of extra dollars." But the Stafne brothers, who’d figured out how to extract electrical power from the rivers on the property and get running water throughout, were not about to be stopped by their Fitzcarraldo-like dilemma. "We’ve gotten to know a bunch of the loggers up here and they know these logging roads," he explains. "We gave them some cash and they hooked the thing up to one of their trucks and just started dragging."

Amazingly, it worked. The frame was pulled to the top of the mountain, and then craned into position on the foundation. The project finally started to experience the effects of prefab’s speedy potential. "The basic structure of the home went up relatively quickly," says general contractor Kyle Keever. "All in all, it took about two weeks to come together once everything was in place."

Prefab’s benefits were enticing, but Stafne also yearned for a truly unique home—representative of his varied pursuits and passions. To that end, he engaged many of his artist friends to help. Woodworker Noah Israel built the stairs that wind through the center of the house, and also lined the interior walls with Douglas fir that was planed five times in order to warm up the space and add texture to the otherwise flat surfaces. Artist Constantin Hapaianu contributed much of the stainless steel work, as well as many of the sculptures, while Brian Stephens and Dennis Coons completed much of the exterior landscaping and earth work around the house. Artist Larry Stauffer also designed much of Stafne’s artwork specifically for the house. With this creative collaboration, the house, as Stafne is fond of saying, "really feels like a work of art."

While these flourishes have been critical to the structure’s ability to be a home rather than just a steel box, they’ve also been the culprit in many of the cost overruns that have been perturbing to all involved. "We were hoping to get this place built for $150,000 to $200,000," Stafne says. "But that just didn’t happen. It came out to be much more. There are still so many unknowns and unforeseen difficulties that can occur."

Despite all the problems, one would be hard-pressed to argue that the project has been anything but a success. And if the home didn’t meet all of Stafne’s budgetary goals, it has certainly made him happy. "Once the house went up, it was incredible," he says. "I don’t know if any of us could have appreciated the views we were going to get—the home we were going to get—until we actually got them." And the house adds an interesting case study to the ongoing research project that is prefabricated building—another rung to the ladder the building industry needs to climb to maximize prefab’s potential.

Looking like a jewel box at dusk, Scott Stafne’s Cantilever House rests easy in the middle of the Washington woods. With miles of hiking trails, lakes, and waterfalls to explore, Stafne’s property provides almost unlimited opportunity for outdoor adventures. The strong and sturdy house acts as a warm respite from the elements when the weather won’t cooperate, which is often—horizontal rain and whipping winds can be the norm.

The design of the Cantilever House, as it's known, is based on a 14-by-86-by-22-foot steel frame resting on a 14-by-31-foot concrete foundation bolted to an existing rock.

The use of structural insulated panels (SIPs) throughout the house helped speed the construction process. Peter Anderson explains, "The panels themselves hang from and rest upon the steel frame and wood spline beam system, which is the link between the steel frame and the panels. The SIPs provide enclosure, insulation, and the spanning capacity to support the cast-concrete floor."

Architect Peter Anderson explains that "the floating nature of the design would not have been possible with conventional onsite framing techniques, nor any of the currently marketed modular home designs." Using a heavy structural steel frame, engineered wood spline beam system, and structural insulated panels, the architects created a truly unique hybrid structural system and, in the end, a home.

The living room looks out toward the two waterfalls that are also part of the property and the inspiration for its name. Artist Constantin Hapaianu made the coffee table and the stainless steel railings surrounding the staircase.

The stairs and the wood paneling were designed and built by wood-worker Noah Israel, a longtime neighbor and friend.

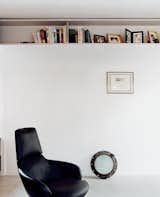

Stafne’s office showcases his ingenious use of the steel structure of the house as a handy bookcase.

Published

Last Updated

Get the Dwell Newsletter

Be the first to see our latest home tours, design news, and more.