Santa Rosa Fire Rebuild - New Beginnings

Credits

From BONE Structure

Over a year ago, on October 9, 2017, a fast-moving wildfire sparked by a downed PG&E power line swept through Sonoma in the middle of the night. On the morning of October 10, Howard Booster hiked over a ridge in Santa Rosa to the place where his multi-generational family home of 35 years once stood.

He found nothing left. It was not even smoldering. It was just gone.

The home survived the wildfire itself, but the embers had blown up into the soffit vents. Two or three hours later, it burned from the inside out. When he walked over to his garage, it looked like the ground was covered in Italian tiles. The charred asphalt shingles, the only thing left of the building, littered the ground. (This is one of the ways he confirmed the buildings burned from the inside, and according to fire officials, hot embers entering through vents was a common cause of homes burning in this disaster that destroyed thousands of homes in a single night.

After much thought, the Boosters have begun the process of rebuilding. The new home will be a super-energy-efficient, 100% solar, net zero energy home thanks to the collaboration between their architects Brendan Kelly and Kerry Morgan with BONE Structure®, which makes a net-zero-energy ready framing system to fit the design “Eliminating things like vents in a BONE Structure house is easy because of the way it goes together with steel and spray insulation,” Brendan explained.

At first, Brendan and Kerry tried to put nonflammable cement panels on the design, but they couldn't imagine Merritt and Howard with steel and minimalist architecture.

“I remember being in Palo Alto at their wedding. It was a classic hippie wedding. Merritt was the poster child for the hippy bride with flowers in her hair,” Brendan says. So, he found an FSC-certified machiche wood from Asia that will go over the top of spray insulation, which he feels is more suiting. Choosing wood over cement panels doesn’t feel like a safety compromise to Brendan. “There’s no such thing as a fire proof building. It's a false choice,” he says. “So many Class A materials still burn at 800 degrees Fahrenheit. When you have a super-hot fire [like the Sonoma fire], even concrete melts.” “When BONE Structure understood why cladding the structure in wood fit better with the character of the Boosters, they went with it. It's a very collaborative process. They were right in there with us,” he says.

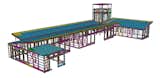

The Tower and the Breezeway

Brendan and Kerry, who met in their first year of architecture school at University of Washington, lived in Italy for a year during school. They called on this experience for this design. The home resembles an Italian (or Sonoma) agricultural building. They aligned the entire building around the best view and the wood screens on the windows can close.

The home features a prominent tower on one end, which Brendan says was a folly. “Follies usually get whacked out because of budget. Howard wouldn't let us take it off. Kerry redrew the tower many times.”

The tower will be a lantern for the neighborhood; a fire lookout; a place to play fiddle; and a place for grandkids to camp out. Every other slat is missing to let light in and a window faces east.

A covered California-style breezeway runs through the middle of the building, in part to let the traffic through for family gatherings and public functions—the house concerts Howard and Merritt will resume there. Visitors will enter on the west and come out looking at the crest of a beautiful hill on the east side.

“I kept expecting BONE Structure to try to do things with this design and they never did,” Brendan says. “They all love the design and wanted BONE Structure to work with the design. I got everything into a five-foot grid to work with their system.”

A few things are different for this home than the usual process. In working with the BONE Structure system, structural engineer fabrication team decisions happen earlier. They usually happen in the field, Brendan says.

Howard's most frustrating part of the process was the time it took at the beginning. “We got the permit in July but because the concrete pad is so important, we had to wait to find a qualified team to pour it due to the high demand for contractors in the area,” Brendan explains.

A massive advantage, however, is how fast a BONE Structure house goes together. BONE Structure will deliver the pre-fabricated framing. Then, BONE Structure field expert Alex Tureck will help Mikara Construction, headed up by Mike Dethlefsen, to build out the roof, windows, HVAC, plumbing, electrical, interior finishes, cabinetry and so on. Mike’s team will do the heavy lifting once the design is complete and delivered by BONE Structure. The exterior of the building will go up in a few weeks and Mike’s team will outfit the interior through Northern California’s rainy season this winter. The Boosters plan to move in the summer of 2019.