A Simple DIY Modular Home Kit That’s Anything but Mundane

In 2017, Australian architect Adriano Pupilli designed IMBY ("In My Back Yard") as a building system that would provide flexibility, ease of construction, and affordability for small residential structures such as a backyard pavilion or guest house. Pupilli’s design sought to bring good, sustainable design to the wider public through the development and creation of a sustainable modular building kit.

IMBY, short for "In My Backyard," was conceived of as a way to combine elegant design with traditional woodworking techniques to create something that is efficient and sustainable and employs modern digital fabrication methods.

The goals for IMBY were multi-faceted: it needed to have minimal impact to existing plant and wildlife, be fabricated from renewable materials, and be assembled, disassembled, and stored flat as the owners might need. Flexibility and simplicity were key for quick and easy construction that could potentially be done by the owners themselves, and equally important was good architectural design that incorporated high-quality materials and natural light.

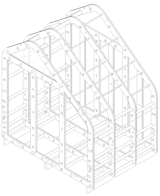

A critical component to IMBY is the method of on-site construction, which is simple enough to be completed by non-skilled labor. The framing fits together using interlocking pieces, and is cut out of sheets of plywood by using the most efficient layouts possible.

Pupilli’s solution is a modular series of wood-frame arches that form the ribs, or structural bays, of the module. Lightweight and portable even to sites with challenging access, the prefabricated framing arrives flat-packed and can be disassembled and relocated as necessary. Assembly is completed with interlocking timber joints, so specialized construction equipment isn’t necessary.

Typical IMBY models have at least one of the end-gable facades made out of glazing to allow for natural light to come in. At this IMBY in Neutral Bay in New South Whales, Australia, a family used a 4-bay structure to create an extra play space for their young children.

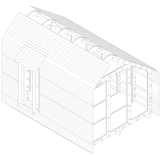

IMBYs are designed almost entirely with FSC-certified plantation timbers and quality plywood, such as Ecoply, that complies with building codes and standards. The structures typically feature plywood parts and acrylic windows, plywood flooring, birch lining, a skylight at the peak of the symmetrical gabled roof, and a choice of Colorbond steel or Western Red cedar as exterior cladding.

Interiors can be left unfinished without insulation, allowing for the plywood floors and walls to be expressed, or they can be completely finished for climates and uses that might require it.

The structure can extend out by adding additional bays, making IMBYs perfect for everything from backyard storage sheds that can be as small as two bays deep to a whole studio at 12 bays deep.

The asymmetrical gable of the roof and its curved peak are subtly modern but still functional, allowing the angle of the roof to shed rainwater but still keeping the ceiling height at an appropriate level for adults.

Even with this broad range of uses, prices remain affordable: a two-bay kit at 6-and-a-half feet long, nine feet wide, and nearly ten feet high costs $6,390 AU (about $4,400 USD) for the Frame and Features package, which includes the precision-machined plywood parts and acrylic windows. Off-the-shelf components, such as cladding insulation and alternative finishes, can be purchased, too.

This 6-bay IMBY located in Katoomba is used by a married couple as a studio and garden room. The structure was put together over the course of two weeks by one of the homeowners.

Pricing for an 11-bay IMBY that is about 25 feet long and suitable for guest rooms and studio-type homes starts at $16,770 AU (about $11,500 USD). Additional elements such as different types of furniture and windows are also available as add-ons.

Operable windows are an additional element that can be incorporated into the standardized framing system; they're available in three different types, along with deck bays, a special glazed rear entry, and furniture that employs the same interlocking joinery as the IMBY structure.

While not available at the moment in the United States, three IMBY houses— used as everything from a beachside home office to an urban play space—have already been erected in New South Wales, Australia, with more to follow.

IMBYs are created by using interlocking joinery techniques, eliminating the use of typical construction mechanical fasteners like screws and nails. This allows for the completion of the series of structural bays that then receive cladding, windows, and furniture as desired.

Cladding on the IMBY can be supplied by the builder or purchased as one of two options through IMBY: Western Cedar shingles or Colorbond steel siding.

IMBYs are available in a range of sizes, from smaller two-bay structures to up to about 12 bays long.

Published

Topics

Prefab HomesStay up to Date on the Latest in Prefab Homes

From cozy cottages to large family houses, see how prefab continues to redefine the future of construction, building, and design.