New “Metallic Wood” Is as Strong as Titanium But Much Lighter

Titanium has long been touted as the metal of the future, due to its strength, rust resistance, and amazing lightness. But it's not as strong as it could be, due to random defects in the way its atoms are stacked during the manufacturing process.

Researchers at the University of Pennsylvania’s School of Engineering and Applied Science, the University of Illinois at Urbana–Champaign, and the University of Cambridge have discovered a way to work with the individual atoms in metal to design and build a new material. One that is as strong as titanium but five times lighter, according to their study published in Nature Scientific Reports last month.

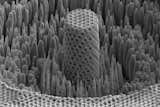

The team, headed by James Pikul from Penn Engineering, have developed a material they are calling "metallic wood." Its porous structure provides a high strength to weight ratio and also mimics more natural properties found in wood.

"The reason we call it metallic wood is not just its density, which is about that of wood, but its cellular nature," Pikul says. "Cellular materials are porous; if you look at wood grain, that’s what you’re seeing — parts that are thick and dense and made to hold the structure, and parts that are porous and made to support biological functions, like transport to and from cells."

That porosity creates empty space in the "metallic wood," which could be infused with other materials, organic or inorganic. For example, a prosthetic leg made from this material and infused with anode and cathode materials, could also be a battery.

So far, the researchers have built a sheet of nickel with nanoscale pores that is almost 70 percent empty space, and as strong as titanium but much lighter. It was created by building tiny plastic spheres, suspending them in water, allowing the water to evaporate, and then electroplating the spheres with nickel. Researchers then dissolved the plastic spheres, producing an incredibly strong, porous metal that will float on water.

Use cases for the material are still unknown, as so far it hasn't been produced on a macro scale.

"We don’t know, for example, whether our metallic wood would dent like metal or shatter like glass." Pikul says. "The long-term interesting thing about this work is that we enable a material that has the same strength properties of other super high-strength materials, but now it’s 70 percent empty space. And you could one day fill that space with other things, like living organisms or materials that store energy."

To learn more, read Penn Engineering's article on Medium and the original study in Nature.

Published

Topics

Design NewsGet the Pro Newsletter

What’s new in the design world? Stay up to date with our essential dispatches for design professionals.